Ten Years of Reliability Your Trusted Partner

Table of Contents

Chapter 1. What are the Different Types of Dump Semi Trailer?

Chapter 2. Dump Semi Trailers Capacity Dimensions Specification

Chapter 2.1 Dump Semi Trailer Specification

Chapter 2.2 Dump Semi Trailer Drawing

Chapter 2.3 Dump Semi Trailer Dimensions

Chapter 2.4 Dump Semi Trailer Capacity

Chapter 2.5 Dump Semi Trailer Application

Chapter 2.6 Dump Semi Trailer Images

Chapter 2.7 Dump Semi Trailer Advantage

Chapter 2.8 Dump Semi Trailer YouTube Video

Chapter 3. What is the Difference Between a Dump Semi Trailer and an Howo Dump Truck?

Chapter 4. The Operation Precautions of the Hydraulic Lifting System of the Dump Semi Trailer

Chapter 4.1 Principle of the Hydraulic System of Dump Semi Trailer

Chapter 4.2 Dump Semi Trailer Hydraulic Lift System Maintenance Specification

Chapter 4.3 Dump Semi Trailer Lift and Drop Operation

Chapter 5. How Do you Unload a Dump Semi Trailer?

TITAN dump semi trailer can be used in construction, agriculture and many other fields. They have different shapes and types, divided into field grid (suitable for heavy cargo, such as sand, large stones, etc.) and U-shaped (suitable for dense cargo, such as clay, wet sand, etc.). Roller trailers and rear tilt trailers. Skeleton dump trailers and flatbed dump trailers.

1. Dump Semi Trailer

Dump semi trailer will help you move and unload bulk cargo in a very simple and efficient way. Especially when dealing with large jobs. Operational safety can be well maintained through a well-designed discharge mechanism.

They are commonly used to transport construction materials such as sand, stone, ore and scrap iron. It should be noted that the length of the tipper trailer cannot exceed 12m. Because the roadbed is not hard enough, the longer it is, the easier it is to overturn, causing the dump semi trailer to be scrapped.

The bottom of the U shape dump semi trailer is an inverted trapezoid. The design on the two sides is to center the cargo and load some waste residue, coal and ballast in a concentrated manner, and it is not easy to stick during unloading. At the same time, the U-shaped crate design is also conducive to transportation operations.

Sweep at the end, encounter some clay, no longer need to pick up a hoe. The shovel digs slowly, which is also very helpful for the cleaning of the container. At the same time, the tail plate of the U-shaped container is flat, and the sealing performance will be better, preventing the loaded soil from leaking out of the gap of the container when driving on the road and spreading to wherever it goes. .

Regarding the square structure, there is a card saying that a friend is a car, and the frame structure is the same, but it is different from the bottom plate shape. In fact, it is not. From the perspective of the frame structure, the square box has more reinforced steel beams.

U-shaped compartments will be more practical and stable than square ones, so special compartments can be used for special purposes. The versatility of the regular square compartment is also very friendly to many retail dump truck owners, breaking down the barriers that limit the transport of goods in the cargo box. Each has its own advantages.

2. Side Dump Semi Trailer

Compared with the rear tipping truck, the cargo loading capacity is larger, the unloading speed is faster, and the price is cheaper than that of the rear tipping truck. The interior of the truck is reinforced with horizontal and diagonal pulls to prevent the deformation of the box. It adopts double insurance and one-handed easy operation. The spring has an automatic lock. design.

Side dump trailers are designed to roll for a reason, and you may be forced to unload in areas with insufficient space. In this case, you can use a roll trailer to help save space. The load capacity of a roll tipper may be greater than that of a rear haul tipper trailer.

The rollover truck is suitable for large-scale workplaces, and its maximum carrying capacity can reach 80-100 tons. Its body length can be 8 meters to 12 meters, according to the needs of customers.

3. Container Dump Semi Trailer and Flatbed Dump Semi Trailer:

Container dump semi trailer and flatbed dump semi trailer are widely used, mainly for handling 20ft and 40ft containers. The Flatbed dump semi trailer has 4 flip brackets, which can make the rear end load more evenly when unloading, and it is not easy to damage the trailer.

4. Howo Sinotruk Dump Truck

According to your requirements, the engine can choose 290~420hp. Choosing a short wheelbase can improve the strength of the frame and the passability of the vehicle.

For tipper systems, you can choose between mid-roof or front-roof. These dump trucks are usually driven on urban roads with a driving distance of less than 200 kilometers. 336hp or 380hp engine power is the best choice. Choose a 6X4 or 8X4 tractor according to load capacity. For the transportation distance of more than 200 kilometers, it is best to use 8X4 for more loading.

Howo Sinotruk dump truck has won the hearts of so many African customers due to its power, stability, and low cost of maintenance. You can choose a 6x4 10 wheeler Howo Sinotruk dump truck cargo body with Front lifting type or Middle lifting type which you preferred. The hydraulic system using HYVA brand or Domestic.

Dimension: 11280mmx2495mm x3970mm ( inside dimension )

Main beam: Height: 480mm-500mm, Upper plate: 16mm-25mm, Middle plate: 12mm-20mm, Lower plate: 18mm-25mm, Material: T700 steel.

Tare Weight (semi trailer): About 15600kg

Total volume(m³): 30-45m³ or less than 100tons

Side wall thickness: 4 - 6mm

End plate: 8mm

Lifting System: Full set of HYVA lifting cylinder

Axle: 13T/16T, FUWA / BPW / TITAN Brand

Rim: 8.0-20 or 9.00-20

Tire: 8.25R20/10.00R20/11.00R20/12R22.5

Suspension: Mechanical suspension

Spring leaf: 90(W)mmx13(Thickness)mmx10 layers

Kingpin: JOST brand 2.0 or 3.5inch(bolted or welded type)

Landing gear: JOST brand

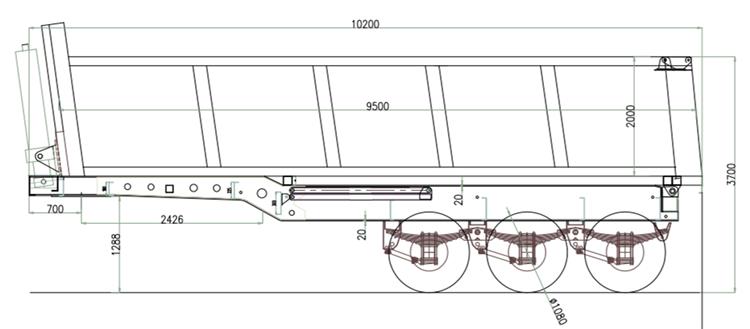

Drawing of U Shape Dump Semi Trailer

Drawing of U Shape Dump Semi Trailer

Drawing of Tri Axle 40 Ton Dump Truck Trailer

Drawing of Tri Axle 40 Ton Dump Truck Trailer

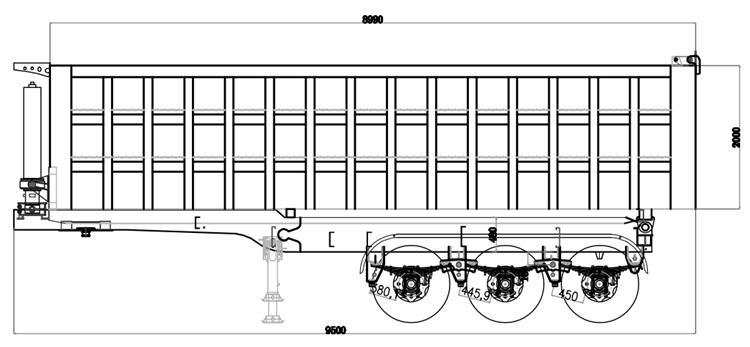

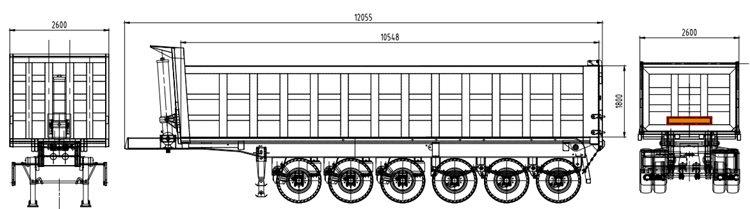

Drawing of 6 Axle 45 CBM Dump Semi Trailer

Drawing of 6 Axle 45 CBM Dump Semi Trailer

3 Axle Dump Semi Trailer Dimensions: 9000*2500*3480(mm)

3 Axle U Shape Dump Trailer Dimensions: 10000*2500*3500(mm)

4 Axle Dump Semi Trailer Dimensions: 10500*2500*3500(mm)

5 Axle Dump Semi Trailer Dimensions: 10880*2500*3500(mm)

6 Axle Dump Semi Trailer Dimensions: 12000*2600*3500(mm)

TITAN dump semi trailer can carry 30-80 ton goods. 25-45cbm/cubic/m3. We often sell 38 ton, 40 ton, 45 ton, 60 ton dump semi trailer, 40 cbm, 45 cbm dump trailer.

TITAN dump semi trailer widely used in sandstone plants, construction sites and mines to transport sand, gravel, earthmoving and mining.

3 Axle Dump Semi Trailer

3 Axle Dump Semi Trailer

4 Axle Dump Trailer for Sale

4 Axle Dump Trailer for Sale

5 Axle 60 Ton Dump Truck Trailer

5 Axle 60 Ton Dump Truck Trailer

6 Axle 45 Cubic Dump Truck Semi Trailer

6 Axle 45 Cubic Dump Truck Semi Trailer

Heavy-duty models are double vertical plate beams, which have the stronger bearing capacity and are not easy to break. 4 sub-beams (some heavy vehicles will use 6 sub-beams), are anti-distortion and stronger.

At the intersection of the sub-beam, the triangular plate is used for locking and reinforcement to prevent deformation and cracking. There is a balance beam at the front and rear of the frame to prevent the vehicle from rolling over and increase the stability of the body. 4 heavy-duty flip brackets are more stable and firm, and the brackets are independent. The rear door adopts a double buckle design, which is more secure.

Use an external power take-off to pressurize the hydraulic oil pump. The hydraulic oil pump controls the pressure of the hydraulic oil to realize the lifting and lowering of the hydraulic cylinder. Generally, it can be completely lifted within 30 seconds to realize unloading.

Through these videos, you can learn about different types of semi dump trailers, as well as the process, testing, packaging and customer feedback, etc.

Dump semi trailer and truck freight are the most commonly used vehicles in logistics. Dump semi trailer is a subdivision of trailers, which is a semi-trailer that can realize the function of self-unloading. Compared with other trailer products, it has the advantages of easy operation, high transportation efficiency, low material surplus rate, and labor saving, so it is a very popular trailer in the logistics transportation market.

1. The weight of the cargo is different

The Howo dump truck itself is small in size, and the weight of the cargo loaded when carrying the cargo is also small. Because of the car body, the operation is very flexible, and the Howo dump truck is very convenient in places where the road is narrow and the road is rough.

However, if it is a large coal mine or a large-scale project, the labor and cost of truck freight is much higher than that of dump semi trailer. Tri axle dump semi trailer is more suitable for use in these aspects. times, which can shorten the engineering time and improve the efficiency.

2. Different self-unloading methods

Carrying coal mines needs to be transported to a certain place, and then loaded and unloaded. Coal mines loaded and unloaded by Howo dump trucks can only be turned over backward. It is very inconvenient to simply use the back, unload it to a fixed place, and need to adjust it. Unload the goods according to the regulations.

Due to the limitation of the site, it is also very inconvenient to unload the goods. However, the dump semi trailer unloading method has two forms: backward rollover and rollover. There will be no inconvenience due to the venue, and it is more convenient to unload the goods.

3. The quality of the carriage is different

Dump semi trailer is welded with a high-quality manganese plate, which has a long service time and good toughness. The material of other carriages is not good enough, and the carriages will suffer from severe corrosion and damage, requiring frequent maintenance. This is not enough to ensure the cleanliness of the vehicle itself.

Howo dump truck is convenient to transport small bulk cargo, it is small and exquisite, and the cost of manpower and material resources is low; however, dump semi trailer is a wise choice for large cargo transportation and loading and unloading. It is easy to load and unload, and it can pull a lot of things at one time. In long-term transportation, the dump semi trailer is better.

Operate the power take-off device of the dump semi trailer to drive the hydraulic pump to work. The hydraulic pump sucks the hydraulic oil in the hydraulic oil tank through the low-pressure oil inlet pipe and generates high-pressure oil for output. The high-pressure oil output by the gear pump enters the lift valve through the high-pressure oil pipe and lifts the oil.

The lift valve delivers high-pressure oil to the oil cylinder or drains it into the hydraulic oil tank under the control of the air control valve to realize the lifting, intermediate stop and lowering functions of the hydraulic oil cylinder.

The upper and lower brackets of the oil cylinder should be filled with grease (butter) in time. It is recommended that the oil cylinder be filled with grease once every 120 times or every 15 days. It needs to be filled with grease again before returning to use after long-term use.

The Dump semi trailer should be lifted slowly during the running-in period. In principle, the engine speed should be controlled at about 1000 rpm, and it should not exceed 1500 rpm after the running-in period.

Check the hydraulic oil every week for discoloration and deterioration. If there is discoloration and deterioration, it should be replaced in time. The hydraulic oil should be changed according to the region and season. Generally, it is more appropriate to change the oil in April and October. If the oil is found to be insufficient, it should be replenished in time. The specific area and recommended oil are shown in the figure below.

Due to the existence of iron filings and other impurities in the hydraulic system during the running-in period of the dump semi trailer, the hydraulic oil should be replaced and the hydraulic oil tank should be cleaned when lifting about 300 times.

The high pressure oil pipe must be replaced every two years. If the hose is found to be leaking, damaged or partially bulged or cracked during routine maintenance, it should be replaced in time.

Check the oil return filter element and air filter element inside the hydraulic tank every half month for debris and clean it, and replace the oil return filter element and air filter element of the hydraulic tank every six months.

Lifting operation sequence:

1. Open the car tarpaulin or lid

2. Open the rear door lock

3. Depress the clutch with the transmission in neutral and wait 5 seconds

4. Combined with PTO

5. Shift to a low gear (below 4th gear)

6. Put the air valve handle in the up position

7. Release the clutch and the dump semi trailer starts to lift. You can step on the engine accelerator properly but it must be controlled within 1500 rpm

8. When the cylinder reaches the maximum stroke or the limit valve works, put the handle of the air control valve in the middle stop position.

Descending order of operations:

1. Depress the clutch and wait 5 seconds

2. Disengage the PTO

3. Disengage the transmission gear

4. Release the clutch

5. Slowly turn the handle of the air control valve from the stop position to the descending position (the air control valve of the dump semi trailer hydraulic lift system is a proportional control valve, which can control the descending speed of the oil cylinder. The closer the handle is to the descending position, the faster the descending speed of the oil cylinder)

6. After the car body is completely lowered, wait 30 seconds and place the handle of the air control valve in the stop position.

1. Before unloading, make sure that there is no one on both sides and behind the dump semi trailer, and check whether the lift limit device of the dump semi trailer is in good condition.

2. After the dump semi trailer lifting operation is completed, before driving, be sure to turn off the power take-off switch of the semi-trailer to separate the power take-off from the gearbox and stop the oil pump. Then put the manually-operated valve in the intermediate stop position to avoid the danger of automatic lifting while driving.

3. The Dump semi trailer can drive only after the carriage is reset to the upper wing of the subframe. Since the dump semi trailer is in a hoisting state, it is very prone to failures and accidents.

4. The dump semi trailer cargo is evenly distributed, and it is strictly forbidden to move or dump with partial load.

Unload a Dump Semi Trailer Precautions

1. The hydraulic oil tank of the TITAN dump semi trailer is a special lifting cylinder. Do not use the cylinder as a stabilizing support for the body of the dump trailer.

2. Do not let the cylinder be exposed to the air for more than 2 hours (more than 30 minutes in humid air) in the lifted state, otherwise it will cause the cylinder to oxidize and rust.

3. It is forbidden to disassemble and adjust the relief valve on the poppet, otherwise the hydraulic system will lose its safety protection function and cause an accident.

4. When loading goods in the Dump semi trailer, it should be ensured that the front, back, left and right are evenly loaded. If there is too much cargo ahead, it may overload the hydraulic system. Too much cargo behind the dump semi trailer will cause the dump semi trailer to tip over when unloading, and the eccentric load on the left and right will easily cause the cylinder to tip over.

5. When unloading, please make sure that the ground around the dump semi trailer is firm and level, keep it stable, and make sure it is in a straight line.