Ten Years of Reliability Your Trusted Partner

Chapter One: What is SPMT?

Chapter Two: Why SPMT is widely used in shipbuilding and construction?

Chapter Three: Different types of SPMT(self-propelled modular transporter)

Chapter Four: Different types of SPMT(self-propelled modular transporter)

Self-propelled modular transporter (SPMT) is used to transport heavy cargo such as sections of a ship, the whole ship or a prefabricated section, which in most case is more than a hundred tons. Other heavy haulers cannot transport such cargo because of its weight and length. The SPMT trailers are also widely used to carry over length goods that other heavy haulers cannot transport.

A SPMT(self-propelled modular transporter) is a special vehicle that has three major functions including hydraulic driving, hydraulic steering, and hydraulic lifting. A hydraulic system is used to drive each of these functions.

An SPMT can drive the cradle that bears heavy loads, use its hydraulic lifting system to lift up heavy loads, and then transport the loads to the right destination. The transporter does not any hoisting equipment or a crane for the functions. One person can control all the functions until the load reaches its designated place.

Self Propelled Modular Transporter Trailer for Sale

1. SPMT trailers have the highest loading capacities in the world. For this reason, engineers use them to transport bridge sections and large ships.

The self propelled modular transporter trailer can be coupled together to increase their capacity. Hence, they can transport wide and long construction equipment.

2. Another reason why SPMT trailers are widely used in construction plants is that they enable builders to increase their efficiency. The speed of transporting construction materials and equipment is greatly increased with modular transporters. In the past, it would take several months to replace an old bridge.

But now, concrete components are fabricated off-site and transported to the site. It takes only 22 minutes to replace a whole bridge section.

3. Another reason why SPMT trailers are popular is that they enable construction companies to reduce overall costs. When ships and concrete components are fabricated off site, constructors are able to save on the materials. Hence, the overall cost of construction projects is reduced. The projects are completed faster and at a reduced cost. The construction teams can allocate enough time for curing concrete components.

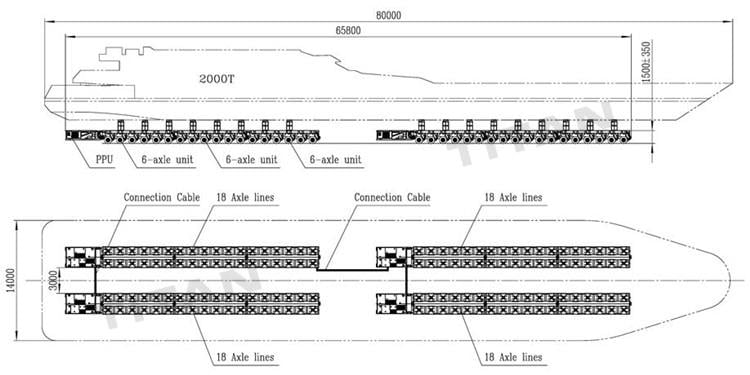

Ship transportation planning drawings

The normal transport capacity of the SPMT ranges from 90 tons to above 16,000 tons. Some of the massive objects that the SPMT transport include bridge sections, huge vehicles, and oil refinery equipment.

Although SPMT trailers are used to lift, transport, and install the heaviest structures in the world, they come in different types. The capacity, features, and uses vary from one type to another. There are many ways of categorizing all the SPMT trailers. The major way that modular transporters are categorized is in their steering systems.

Two major types of steering are used in SPMT trailers that include mechanical steering and electronic.

1. A mechanical steering self-propelled trailers has a rated loading capacity of 180 tons and a dead weight of 30 tons.

When the SPMT is empty, it can move at a 10 km/h. When it is fully loaded, it travels at 5km/h. The low speed is expected because of the heavy loads that they carry.

Its axles have a turning radius of ±55 degrees. The SPMT has four braking axles and a traction force of 640KN. The transporter is about 13000mm long while its platform is 9000mm. Hence, any load within the 9000mm length can be carried with the SPMT.

Its lowest height is 875mm. These dimensions are very important when you are looking for a self propelled trailer for your business.

You must consider the average height and length of your regular freight to pick the right modular transporter. The wheelbase is 1500mm and the tread 1800mm. The total lifting stroke for the SPMT is 600mm.

2. Electronic steering SPMT (Self-propelled modular trailers) have different dimensions, features, and capacities. This kind of SPMT is a large platform with dozens of wheels beneath.

It is different from as mechanical steering trailers in that it has an electronic multi-way steering system. The SPMTs have different bolt-joint combinations. Some have lateral and longitudinal mechanical bolt joint combinations.

Others have electronic combination modes with no bolt joint. The SPMT has a turning radius of +130 degrees or -100 degrees. The rated load capacity is 216 tons while the deadweight is 30 tons.

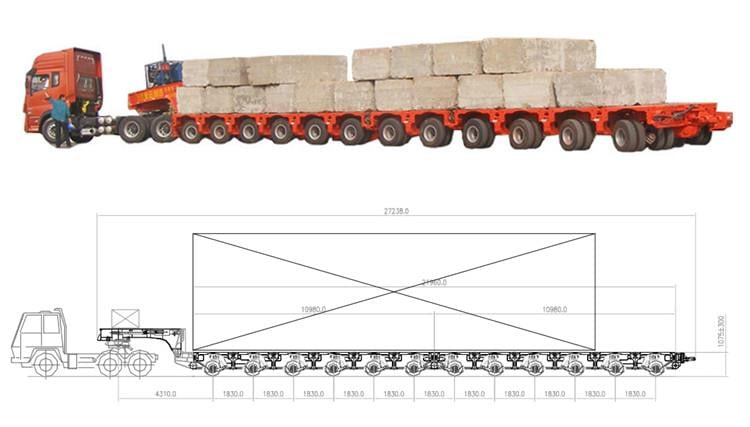

The SPMT trailers have 6 axle lines, 4 drive axles and 8 braking axles. Their grade ability at full load is 7% while that of mechanical steering trailers ranges from 8.5% up to 20%.

The SPMT trailers have a total lifting stroke of 600mm, a traction force of 320KN, and a wheel base of 140mm. The full length of the transporter is 12,600mm while the platform is 8400mm long.

The hydraulic system consists of five major parts with different specifications and functions.

The parts include the hydraulic brake system, hydraulic cooling system, hydraulic lifting system, hydrostatic drive system, and hydraulic steering system. Each of these systems is discussed below.

1. The hydrostatic drive system

The system refers to a closed-loop hydraulic system with a variable drive pump. The control type of the variable pump is an electric proportional control (EP).

The drive systems uses pressurise liquid to power the modular trailer. The term hydrostatic, in this case, refers to the transfer of energy or power from flow and pressure. The term does not include the kinetic energy of the liquid flow.

2. The hydraulic steering system

This system is an open-loop system with an open-loop variable pump. The pump has two major functions that include loading sensing and controlling pressure-cutting-off flow.

It can adjust the output flow of the variable pump based the needs of the load. Adjusting the flow also saves energy. The pressure-cutting-off flow control function enables the operator to restrict the variable pump’s maximum output pressure.

The main reason for restricting the pressure is to protect the hydraulic system from potential damages.

3. The hydraulic lifting system

The hydraulic lifting and steering system share the same open-loop variable pump. The hydraulic oil from the variable pump is shared equally between the lifting and steering cylinder.

Consequently, the platform of the modular transporter lifts evenly and remains horizontal when lifting.

4. The hydraulic cooling system

The cooling system consists of two gear motors that drive fans that cool the composite radiator. One gear pump is used to supply the hydraulic oil under great pressure to the two gear motors.

5. The hydraulic brake system

The brake system in a modular transporter and its parking brake work when the hydraulic brake cylinder is pushed and the brake drum released.

The brake cylinder has springs that keep the transporter in the parking brake state when the cylinder has no pressure oil. The braking system has a manual pump, which is used to release the parking brake when there is no power in the vehicle.

6. The hydraulic suspension

The hydraulic suspensions are divided into different wheel bogies. The bogies include wheel bogies with brake, wheel bogies with drive, and wheel bogies without brake.

The hydraulic suspensions consist of a hydraulic suspension cylinder, bogie frame, axle with drive, axle with brake or without brake, rocker arm, and tire.

Shandong TITAN Vehicle Co., Ltd.

Wehcat/Whatsapp: +86 13064064064  BOSS WeChat

BOSS WeChat

E-mail: sales@titanvehicle.com

Add: Shengjing Homeland ,14F , Building B , Bajianbao Rd, Lixia District, Jinan, Shandong, China, 250131