Ten Years of Reliability Your Trusted Partner

The chemical diesel tanker trailer is mainly used for the transportation of various oils and chemical liquids in the petrochemical sector, that is, the transportation of various gasoline, diesel, liquefied petroleum gas, liquefied natural gas and other liquid resins. Because of the particularity of the transported material, the material of the tank body of the chemical truck needs to be determined according to the characteristics of the transported product.

Aluminum plate and aluminum alloy plate, aluminum plate and aluminum alloy plate are light in weight, good in plasticity, easy to form, and have long service life. They are an ideal tank material. However, tanks made of aluminum plates and aluminum alloy plates have low strength and poor carrying capacity. Therefore, it is mostly suitable for shipping aviation fuel, concentrated nitric acid, ice nitric acid, anhydrous alcohol, organic solvents and other chemical products and food items. It is not suitable for shipping compressed gas, liquefied gas and easily decomposable gas.

Tanker Trailer for Sale, 42000 45000 Liters Tanker Trailer Latest Price

Tanker Trailer for Sale, 42000 45000 Liters Tanker Trailer Latest Price

Diesel tanker trailer chassis: The tanker chassis usually adopts the special tanker chassis of Dongfeng, Jiefang, Foton and other large automobile manufacturers.

Tank body part: The tank body is required to have sufficient strength. The inside of the tank body is equipped with anti-washing plates, and the tank body accessories are equipped with manholes, outlet valves, etc., and some tank bodies need to be insulated and equipped with flow meters. For vehicles with two kinds of fuel, the tank can be divided into silos.

Tank plate selection: carbon steel lined rotomolding or stainless steel plate

Tank shape: oval, square circle, round

Chemical pumps: select high-quality chemical liquid special pumps from well-known domestic companies

Function: Separate or separate warehouses to separate different chemicals and liquid foods. 5. There are multiple all-plastic anti-wave baffles inside, which fully pass the high-pressure gas seal test. The tank has high strength, a stable center of gravity, and safe and stable vehicle transportation.

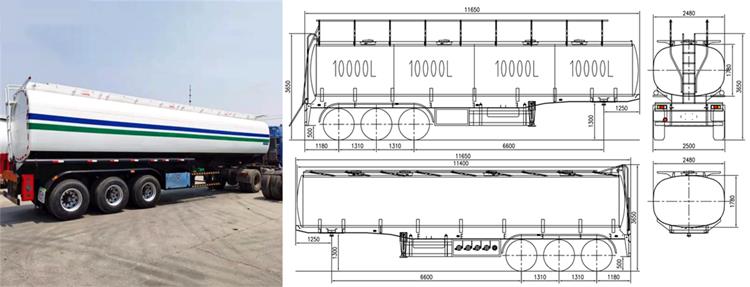

The structure of the Diesel tanker trailer is an elliptical cylindrical or trapezoidal cylindrical body, made of a high-quality steel plate. The whole tank body is divided into single or multiple warehouses. The warehouse can be divided into compartments.

The lower end of the intermediate partition has a through-hole, and the middle of each warehouse is welded with a divided warehouse Or multiple warehouses, the warehouse can be divided into chambers, the lower end of the middle partition has a through-hole, and the middle of each warehouse is welded with a partition reinforced wave partition to reduce the impact of the oil in the tank and improve the rigidity of the tank when the car is running.

42000 Liters Tanker Trailer for Sale with Best Price

42000 Liters Tanker Trailer for Sale with Best Price

In order to prevent corrosion, the surface of the tank is coated with anti-rust paint and decorative paint, and there is a container indicator in the middle of the side of the oil tank, which can directly indicate the volume of the tank when refueling or transporting oil out of the tank. (Optional) The mouth of the tank is a hole with a diameter of 500mm for maintenance purposes.

The large cover is fastened to the can mouth stiffening plate by bolts, and the small cover and the large cover are connected by a support pin and an ear plate. Turn the handle on the small cover clockwise to press the small cover tightly. Reverse, after removing the ear plate, the small cover can be opened, and a breathing valve is installed on the upper side of the big cover.

In order to ensure that the diesel tanker trailer is working, the pressure in the tank is basically the same as the atmospheric pressure, a breathing valve is installed on the large cover of the tank. When the oil in the tank is heated to expand or when the oil pump is used to refuel the tank, the oil level in the tank rises.

The pressure increases. When the pressure in the tank is higher than the external pressure by 8KPA, the breathing valve_upper valve plate opens; when the oil pump is used to discharge oil or the oil is cold and shrinks, the oil level drops and the pressure decreases. When the pressure in the tank is lower than the outside pressure When the pressure is 3KPA, the lower valve plate of the breathing valve opens. It has the functions of self-priming and self-supplying oil and can be divided into two to three different specifications of oil. Double pumps are optional.

3 Axle 45000 Liters Tanker Truck Trailer Manufacturer

3 Axle 45000 Liters Tanker Truck Trailer Manufacturer

Oil pumps: diesel tanker trailer oil pumps are usually self-priming pumps, gear pumps, chemical pumps, stainless steel pumps, centrifugal pumps, and heavy oil pumps.

Operating system: The gearbox is driven by the engine, and the power take-off installed on the gearbox drives the oil transfer pump. The oil transfer pump generates power and pumps the liquid in the tank in or out through the pipe network.

Fire extinguisher: Usually diesel tanker trailer carries 2 sodium bicarbonate dry powder fire extinguishers with the car. Sodium bicarbonate dry powder fire extinguishers are suitable for flammable, combustible liquids, gases and the initial fire of live equipment.

Breathing valve: Breathing valve is a ventilation device fixed on the top of the storage tank to ensure the normal state of the pressure in the tank, prevent the storage tank from being damaged by overpressure or vacuum in the tank, and reduce the loss of liquid in the tank by volatilization.

When the breathing valve dumps 700, the sealing ball in the valve dumps to form an effective seal to prevent oil leakage. The oil measuring hole is installed at the preparation opening on the manhole cover, and a dipstick or liquid level gauge can be installed.

Submarine valve: installed at the bottom of the tank, it can replace the traditional top-loading refueling for bottom-loading refueling, making the operation easier, time-saving, safe and environmentally friendly for the staff. A cut-off groove is designed on the valve body.

In the event of an accident in the diesel tanker trailer, the cut-off groove is disconnected, and the vehicle bottom pipeline is cut off from the tank body without affecting the tank body’s sealing, effectively preventing the oil leakage in the tank and ensuring the diesel Tanker trailer safety.

Safety valve: specially designed for diesel tanker trailers, chemical tanks and other tank products. Different opening pressures can be set according to user needs to meet different needs. The main body is made of integral stainless steel precision casting, corrosion, high sealing, suitable for various environments.

Tank trucks and chemical trucks are mainly used to load and unload acid, alkali, salt and other corrosive and dangerous media. The tank body of the chemical liquid transporter has all-plastic tanks and carbon steel-lined plastic tanks.

Fire Dome Automobile fire dome is usually a vortex valve structure, without any tools, the four-bar mechanism is directly connected to the tailpipe of the automobile exhaust pipe, no switch or connection fixing screw is required, the operation is simple and fast, and the installation and disassembly can be completed in a few seconds. . It can completely extinguish sparks entrained in the exhaust gas of automobile exhaust pipes in places with lower ignition points and higher concentrations of flammable products.

45000 Liters Fuel Tanker Trailer for Sale with Best Price

45000 Liters Fuel Tanker Trailer for Sale with Best Price

1. The use and maintenance of the oil pump of the diesel tanker trailer shall be carried out in strict accordance with its operation and maintenance instructions.

2. Diesel tanker trailer should install electrostatic belt in accordance with the specifications. When static electricity encounters the extremely high concentration of combustible gas remaining in the car, it will explode. The electrostatic belt will frequently rub against the car body, etc., and it can be effectively removed from the space where static electricity is easily generated. Static electricity hazards to ensure that the body is not harmed.

3. Oil tanks and piping systems should be cleaned regularly. The oil tanker regularly checks whether the joints of the pipeline system are well connected and the seal is reliable

4. The safety valve and filter net of the diesel tanker trailer should be checked and cleaned frequently

5. Before refueling operation, you must use a power pole to insert into the wet ground, the grounding tape of the tanker should be grounded, and the static electricity should be maintained during the operation.

6. In order to ensure the cleanliness of the diesel tanker trailer, the oil tank and the oil delivery system should be cleaned regularly, and the internal and external joints at both ends of the oil delivery hose should be frequently coated with lubricating oil, so that the oil tanker trailer is easy and convenient to disassemble and assemble. Clean the tubing in time after each work to ensure the cleanliness in the tubing