Ten Years of Reliability Your Trusted Partner

Table of Contents

Chapter 1:Best quality of TITAN lowbed semi trailer

1-1. Knowledge of TITAN lowbed semi trailer

1-2. Different types of low bed trailer

1-3. Loading test of low bed semi trailer

1-4. TITAN Outlines of extendable low bed trailer and composition

1-5. Titan low bed trailer of package and shipping

1-6. What is the different types of TITAN lowbed semi trailer?

1-7.Semi Low bed trailer from Paraguay customers feedback

1-8.How To Keep Cargo Stable On Low Bed Trailer

1-9.Production Process Of Lowbed Truck Trailer

1-10.How does a low loader work?

1-11. Why Choose TITAN Low loader Trailer?

1-12. Why TITAN low bed trailer price more expensive?

1-13. What is the capacity of a low bed trailer?

Chapter 2:What is a lowbed semi Trailer (lowbed truck for sale/ semi low bed trailer/low bed container trailer/low bed chassis/hydraulic low bed trailer) ?

2-1. What is a lowbed semi trailer?

2-2. Common structure of lowbed trailer.

2-3. Factors to consider when purchasing a low bed trailer.

2-4. Low deck trailer load capacity

2-5. Loading method of low bed container trailer

2-6. Lowbed Trailer load test and marine transportation

2-7. Different Types Ramp of Lowbed Semi Trailer For Sale-Mechanical Ramp VS Hydraulic Ramp

2-8. Semi lowbed Trailer Dimensions

|

TITAN Low bed semi trailer are widely used, mainly for medium and long-distance freight transportation. low bed trailers are commonly used to transport heavy vehicles, rail vehicles, mining machinery, forestry machinery, agricultural machinery, and other heavy-duty cargo.

The low bed semi trailer structure usually adopts a concave beam frame. The lower the center of gravity, the better the stability and safety, and the stronger the ability to transport ultra-high cargo. The front section of the frame is a gooseneck (the traction pin in the front section of the gooseneck is connected to the traction saddle on the tractor, and the rear end of the gooseneck is connected to the low bed semi trailerframe) Cargo platform (the lowest part of the frame), the rear end is the wheel frame (including wheels).

Through this video below, you can learn about different types of lowbed semi-trailers, like 2 axle low bed truck trailer, 3 axle low bed semi trailer, 4 axle low loader for sale in kenya, hydraulic ladder lowbed semi trailer, 150 ton trailer, 100t lowbed for sale in Nigeria, etc.

As well as the process, testing, packaging and customer feedback of low bed chassis, etc.

lowbed for sale in nigeria

tri axle New Low Bed Trailer for sale

40-80ton lowbed semi trailer

4 axle 100ton lowbed trailer

As a professional manufacturer, TITAN VEHICLE low bed trailer has provided many low bed trailers for many countries. We have many more advantages on the low bed trailer cost and quality control. Material and suspension (single point and air suspension) are optional.TITAN Low bed trailers have different capacities, such as 20 tons lowbed trailer, 30 tons semi trailer bed, 50 tons semi low loader trailer, 70 tons lowbed truck for sale, 80 tons lowbed transport and 100 tons lowbed trailer truck, 120 tons lowbed trailer, hydraulic low bed trailer. Each type uses a different number of axles from 2 axle low loader for sale malaysia, 3, 4 axles 100t lowbed for sale in zimbabwe and 7, 8 axles.

1)TITAN Lowbed trailers can have a variety of models, such as drop deck/step deck trailers, 2 axle lowbed trailer, 3 axle semi low bed trailer, 4axle lowbed semi trailer, hydraulic ladder lowbed trailer, mechanical ladder and so on. This low bed trailer normally is used to transport large construction machineries, such as excavators, rollers and cranes.

2)Of course, low bed trailer are also used to transport heavy cargo. Due to the low center of gravity of the lowbed trailer transport, 150 ton lowbed trailer can transport huge cargo and avoid damage to the cargo. Hydraulic lowbed trailer transport is designed to solve the overload problem of large tonnage. Usually, ordinary lowbeds for sale use a structure of two axles and one line, but dolly trailers can have multi-lines, such as 4 axles and 16 tires, and are usually used to transport heavy cargo. Each axle of a dolly trailer loads 50 percent of the weight. Many countries are only allowed to have each axle of a vehicle loading 10 tons.

Low bed trailer and 100t lowbed for sale in Nigeria

All of TITAN low bed semi trailer are tested to ensure that our heavy load trailer are free of problems. All low bed semi trailer is tested for carrying capacity after production is finished.TITAN has dedicated technical staff to guide the operation.

low bed semi trailer for sale

We also recorded a video of the test of the low bed semi trailer, it is more convenient for you to check it.

low bed semi trailer truck, 100t lowbed for sale in zimbabwe

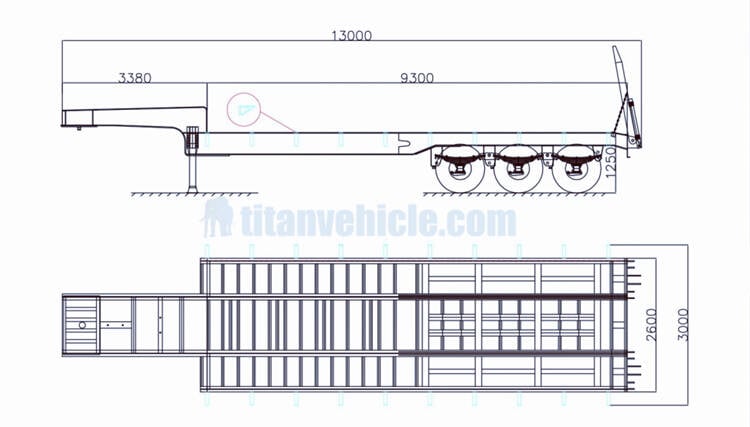

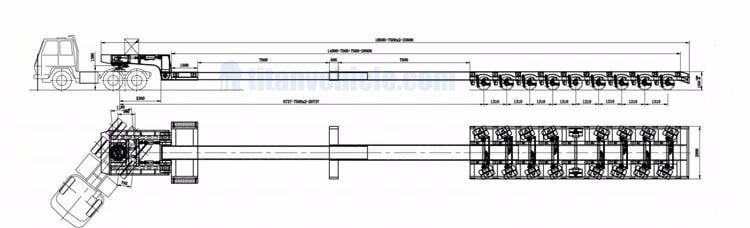

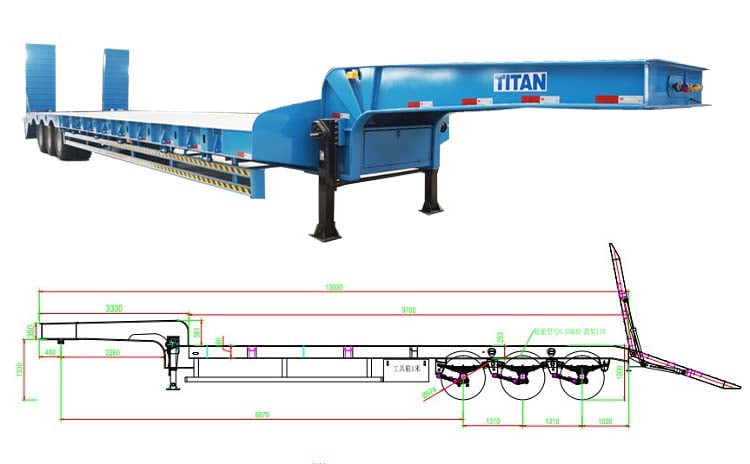

Before production, TITAN technical department must first design and produce drawings according to the needs of the user and the market, so that the technical parameters of the main trailer are matched, and then transferred to the manufacturing department. There are dimensions and specs drawing of different types of low bed trailer. You can learn more details of extendable low bed trailer in the pictures.

Model: TITAN 3 Axle Low Bed Trailer

Loading capacity:60 ton

Overall dimension:13000mm * 3000mm *3400mm

Axles:3 axles

Suspension:Heavy duty mechanical spring suspension

Tire:12 units

King pin:90#

Langing gear:JOST

Electical system:24V, LED lights

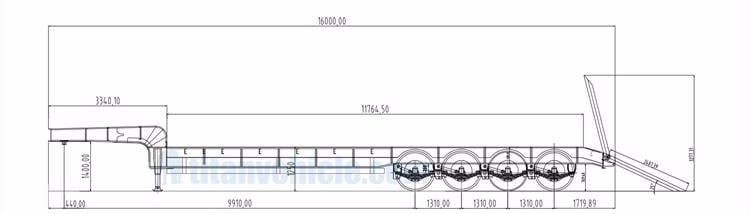

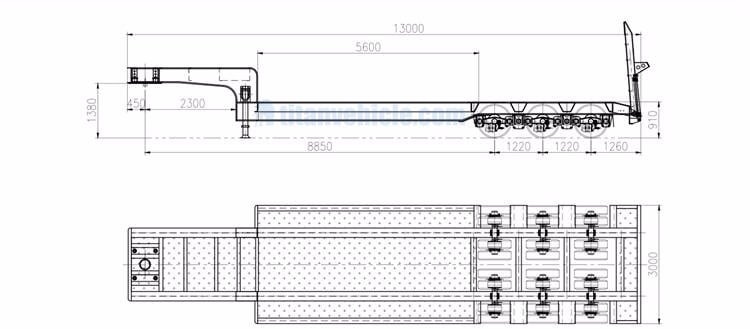

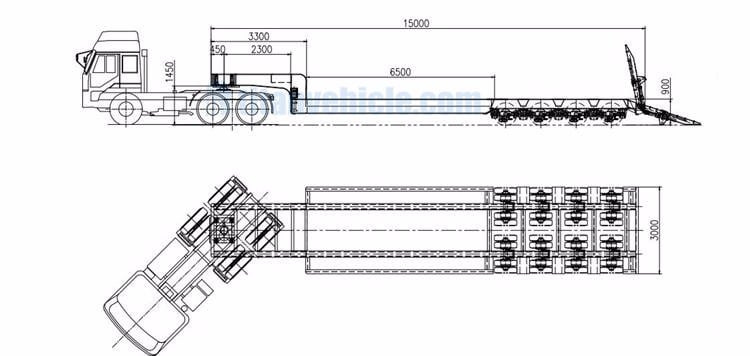

More Technical Parameter Drawings

TITAN 4 axle low bed trailer specification drawing

TITAN 4 axle low bed trailer specification drawing

TITAN 3 line 6 axle low loader trailer technical parameter

TITAN 4 lines 8 axles low bed trailer technical department

TITAN 9 axle extendable lowbed trailer for sale technical specification

TITAN low bed semi trailer have professional staff to make a package, all of them were trained constantly. Please notice that to prevent the low loader trailer paint from being corroded by seawater to we spray a layer of wax on the surface of the lowboy trailer before shipping. And covering poncho to prevent the damp condition.

Lowbed semi trailer of package and shipping

1. Normal type low bed trailer:

This normal-type low bed truck trailer is the most popular type low bed trailer with a loading capacity from 20 - 80 tons, the low bed trailer equipped with 2-4 axles, model for 13-20 ton axles. Usually equipped with the spring ladders for the machines such as the wheel loaders, excavators, or some different types of wheeled machines transportation. The high of the working platform is various from 1000mm to 1200mm.

2. Heavy duty type low bed truck trailer:

Heavy duty low bed trailer is almost the same as the normal type low bed trailers, only comes with a higher loading capacity normally from 80 tons to 140 tons. This type of lowbed trailer is a cost-effective type low loader, usually used for those countries which don't have the special requirements on the axles load and the off-road working environment.

3. Dual lane axles lowbed trailers:

The main specification for the dual-lane low loader trailer is its axles. The dual-lane axle low bed trailer equipped with the short axles, each line has two short axles with 8 sets of tires and rims. This type of low loader trailer is usually used for super heavy equipment transportation. The working platform length will be designed according to the machines that will be transported, tire covered, or exposed types.

The entire cargo platform is straight and above the wheels. The upper space of the overlapping part of the tractor and the excavator trailer is fully utilized so that it has a large cargo platform area. This type of frame structure is relatively simple and easy to manufacture and is mostly used for super heavy trailers.

TITAN can also make different types of low low bed trailer, such as extendabale lowbed trailer, which can be used to transport extra-long goods or wind blades. It can also be used as an ordinary drop deck trailer with multiple functions.

4. Detachable lowbed trailer:

RGN Trailer(detachable gooseneck trailer) also known as a gooseneck lowboy trailer. The container low bed frame has a stepped shape, and the plane of the cargo platform is behind the gooseneck, so that the main plane of the cargo platform is lowered, which is convenient for loading and unloading and transportation of goods. Our lowboy trailer for sale has a detachable gooseneck design on the front, which avoids overturning the body when transporting heavy equipment and ensures the safety of the container low bed and the driver.

Concave beam type, the plane of the cargo platform is concave and has the lowest load-bearing plane. It is generally suitable for transporting large or ultra-high equipment.

5. Extendable low bed trailer:

The extendable lowbed trailer is a kind of special low loader trailer which is designed for the oversized cargo delivery. This type of low bed truck usually doesn't have the ladder, because it's special used for the heavy equipment transportation such as the wind tower transport. Extending low bed truck trailer usually has two types, it's width-extendable and length-extendable, two types. The side extending type low bed trailer is usually used for the width oversized cargo delivery, the width of the extending low bed trailer is different from 3000mm to 5000mm. Length extending type low bed trailer is used for the length of oversized cargo delivery. The length after extended can be up to 25000mm. The special type is the width and length both extendable low bed trailers, usually used for wind tower transportation.

40ft low bed trailer for sale philippines

As a professional lowbed trailer truck manufacturer, Titan Auto has won the favor of domestic and foreign customers for its excellent product quality, low price and perfect after-sales service. The annual output of only 800 semi-trailers is enough to prove the trust and affirmation of customers.

The following is feedback from Zimbabwe harassment customers who received lowbed semi trailers. The customer told us immediately after receiving the low loader trailer for sale and told us that the 40ft low bed trailer reached the destination very smoothly, the packaging was completed and there was no damage. They also hope that the low loader trailer for sale will be put into use as soon as possible and create greater value for them.

low bed trailer for sale philippines

1.Increase the size of the base of support

You can increase the stability of a heavy object by increasing the size of its base of support. Increasing the size does not automatically increase stability. You must increase towards the direction of the oncoming or impeding force.

One way of increasing the base support is to change the position such that the widest part of the object lies on the ground. Another way is to increase the number of contact points with the ground where possible.

For some objects, you may need to change the package or change the position to create an additional contact point.

Also, the lowbed truck for sale transport can widen by some accessories to increase the size of the working platform.

2.Increase friction

The level of frictional resistance between the contact point or points and the base or ground influences the stability of the object. When the level of frictional resistance is low, the object will slip or skid on the ground.

High friction, on the other hand, improves stability, especially on a smooth base. Consider the surface of the contact point and choose to package with a rough surface.

Lay the bottom plate of excavator trailer

Lay the bottom plate of excavator trailer

Sometimes transporters use sawdust on their low loader truck trailer for sale to keep heavy objects with smooth surfaces stable. You can add any other rough material on the floor or base to increase friction as long as it does not damage the object.

3.Lower the center of gravity

The location of the center of gravity from the base of support determines the stability of an object. If the location is high above the base support, the object is likely to be unstable depending on the size of the support base. This explains why tall objects topple over easily.

The way to increase stability is to lower the center of gravity or reduce the distance between the center of gravity and the ground. So the double drop deck trailer is a good choice, it can make the center lower.

Carry high object while lying on the ground or in a leaning position instead of an upright position. When you incline a tall object or any other object, you automatically lower the center of gravity.

4.Lower the speed

Moving an object at a high speed increases its chances of toppling over. Speed does not necessarily affect the amount of gravitational force on an object. However, speed determines the reaction of the object when faced by an external force.

For instance, if you are transporting an object with 4 Axle heavy low loader trailer at a high speed, a sudden stop or hitting an obstacle will cause the object to topple over. Sometimes stepping on the brakes when driving at a high speed causes the object to fall or slide. If you are carrying the object, walking at a low speed helps to keep the center of gravity or balance point at the same position.

welding suspension of low loader truck

welding suspension of low loader truck

5.Driving skills

Place the object at the center of the base of support

The vertical projection of the center of gravity should be at the center of the base of support. In other words, the balance point should be at the center of the base or ground for the object to remain stable.

Placing the object near any of the edges may cause it to fall, especially when the semi low bed trailer or transporter changes its momentum. By placing the object at the center, you increase the distance that the center of gravity has to travel before it can cause the object to fall.

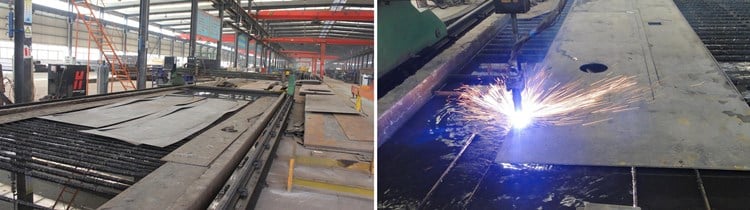

Before production, TITAN technical department must first design and produce drawings according to the needs of the user and the market, so that the technical parameters of the main 40ft step deck trailer and 40ft low bed trailer are matched, and then transferred to the manufacturing department.

1. Stage of cutting steel sheet material

According to the drawings of each part produced by the design department, each part is cut out with a CNC cutting machine, such as beam webs, reinforcement plates, standard small accessories and so on.

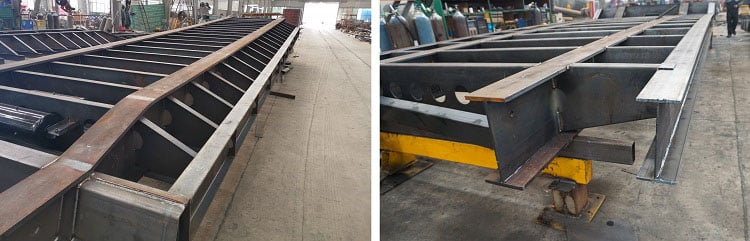

2. Submerged arc welding beams, beams fixed

The second step is to fix the cut web and the upper and lower wing plates to weld points, and then weld the beam by submerged arc welding.

front neck bend 40ft low deck trailer

front neck bend 40ft low deck trailer

3. Opening, calibration beam, through beam

First cut out the web of the beam to cut out U-shaped holes through which the beams can pass, and then fix the welded I-beams in parallel. The result of comparing the beams is very important. If two I-beams have large parallel errors, very serious tire wear will occur.

4. Connect side beams, welding king pins

At this time, the 40 feet low bed trailer of the main beam is basically formed, only the side beams are welded to form the frame structure. And the traction pin traction plate is welded to the position required in the contract, the welding process is required to be high, otherwise, the lowbed truck trailer will be skewed.

5. Welding frame, welding suspension

At this time, the welding suspension must strictly control the size and maintain the squareness, otherwise it will cause 2 axle low loader for sale malaysia of tire wear.

Submerged arc welding beams, beams fixed of low loader trailer for sale

Submerged arc welding beams, beams fixed of low loader trailer for sale

6. Attach the front neck

Drop deck trailer with front neck have this process, and low loader for sale in kenya do not have this process. The front neck of the low bed trailer is welded up. Welding is done to strengthen the plate. There is no problem with the strength. TITAN used 4 axle low loader for sale malaysia have also considered it in advance.

7. Lay the bottom plate

That is, the 40 feet low bed trailer of the bottom plate is fully welded on the frame. There is nothing to say at this step.

8. Frosted and painted

Frosting is the previous step of spray painting. Some manufacturers without shot blasting workshops will blow and polish the welding slag with high pressure gas at this stage.

Spray paint is usually sprayed in a well-ventilated shed. If you want to spray beautifully, you must first look at the coating and the technology of the technicians, but TITAN 40 feet low bed trailer will spray very beautifully. Basically, you don’t have to worry about this. We will be very attentive!

Stage of cutting steel sheet material of lowbed for sale in nigeria

Stage of cutting steel sheet material of lowbed for sale in nigeria

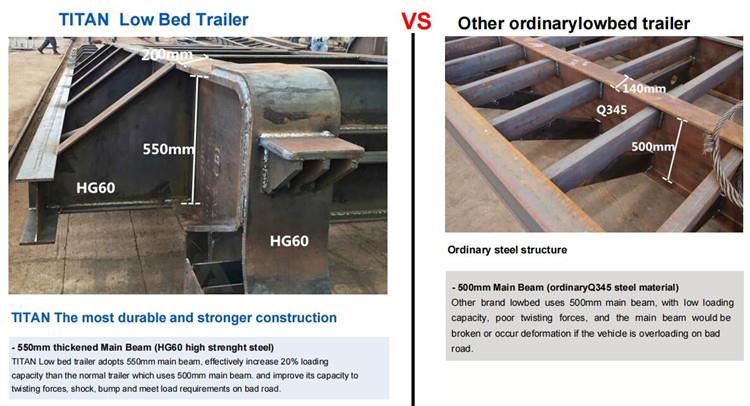

Low Loader Trailers are widely used, mainly for medium and long-distance freight transportation. Its frame is a beam-through structure, and the longitudinal beam adopts a straight and live gooseneck type. The height of the webs ranges from 400mm to 550mm, the longitudinal beams are welded by automatic submerged arc welding, the frame is shot blasted, and the beam penetrates the longitudinal beams and welds the whole.

Low Loader Trailers use high-strength international steel material, the vehicle has a lightweight, and guarantees its anti-torsion, anti-vibration, anti-bump ability, and meets different load bearing capacity.

Composed of tandem dry plate spring and suspension support, the structure is reasonable, with strong rigidity and strength, used to support the load and buffer the impact. Low Loader Trailers are usually used to transport heavy vehicles, such as tractors, buses, and special vehicles. Rail vehicles, mining machinery, forestry machinery, agricultural machinery, such as excavators, bulldozers, loaders, paving machines, cranes, etc. And other heavy-loaded goods, the lower the center of gravity, the better the stability and safety, and the stronger the ability to transport ultra-high goods and pass overhead obstacles.

2 Line 4 Axle Low Loader Trailer For Sale

2 Line 4 Axle Low Loader Trailer For Sale

When loading mechanical equipment on Low Loader Trailers, the mechanical equipment is usually loaded from the rear of the semi-trailer, that is, the mechanical equipment is moved from the rear wheel frame or the wheels are removed, and then the mechanical equipment is fixed on the semi trailer.

1.Increase the size of the base of support

You can increase the stability of a heavy object by increasing the size of its base of support. Increasing the size does not automatically increase stability. You must increase towards the direction of the oncoming or impeding force.

One way of increasing the base support is to change the position such that the widest part of the object lies on the ground. Another way is to increase the number of contact points with the ground where possible.

For some objects, you may need to change the package or change the position to create an additional contact point.

3 Line 6 Axle Low Loader Price

3 Line 6 Axle Low Loader Price

2.Place the object at the center of the base of support

The vertical projection of the center of gravity should be at the center of the base of support. In other words, the balance point should be at the center of the base or ground for the object to remain stable.

Placing the object near any of the edges may cause it to fall, especially when the truck or transporter changes its momentum.

3.Lower the center of gravity

The location of the center of gravity from the base of support determines the stability of an object. If the location is high above the base support, the object is likely to be unstable depending on the size of the support base.

This explains why tall objects topple over easily. The way to increase stability is to lower the center of gravity or reduce the distance between the center of gravity and the ground. So the double drop deck trailer is a good choice, it can make the center lower.

Details of Low Loader Trailer

Details of Low Loader Trailer

4.Increase friction

The level of frictional resistance between the contact point or points and the base or ground influences the stability of the object. When the level of frictional resistance is low, the object will slip or skid on the ground.

High friction, on the other hand, improves stability, especially on a smooth base. Consider the surface of the contact point and choose to package with a rough surface.

Sometimes transporters use sawdust on their trucks to keep heavy objects with smooth surfaces stable. You can add any other rough material on the floor or base to increase friction as long as it does not damage the object.

5.Lower the speed

Moving an object at a high speed increases its chances of toppling over. Speed does not necessarily affect the amount of gravitational force on an object. However, speed determines the reaction of the object when faced by an external force. If you are carrying the object, walking at a low speed helps to keep the center of gravity or balance point at the same position.

The capacity of a low bed trailer can vary depending on its design, manufacturer, and specific model. Low bed trailers, also known as lowboy trailers, are designed to transport heavy and oversized loads that exceed the legal height limits for standard trailers.

The capacity of a low bed trailer is typically determined by its load-bearing capacity and axle configuration. These trailers are constructed to distribute weight evenly and withstand heavy loads. Some low bed trailers can have a capacity ranging from 40 to 150 tons or more, depending on the number of axles and the specific engineering and structural features.

It's important to note that the capacity of a low bed trailer is subject to local regulations, road restrictions, and specific permits required for transportation of oversized loads. Additionally, factors such as the trailer's condition, tires, suspension, and other specifications will also impact its actual load-carrying capacity.

To accurately determine the capacity of a specific low bed trailer, it's best to refer us, TITAN can provide precise information based on your needs.

The load capacity of a low bed trailer is determined by several factors, including:

1. Gross Vehicle Weight Rating (GVWR): The GVWR is the maximum weight limit that the trailer, including its own weight and the weight of the load it can carry safely. It takes into account the structural integrity of the trailer, the strength of its components, and its suspension system.

2. Axle Configuration: The number and arrangement of axles on the low bed trailer play a significant role in determining its load capacity. Trailers with more axles can distribute weight more evenly and handle heavier loads. Common axle configurations for low bed trailers include two axles, three axles, and multi-axle configurations.

3. Suspension System: The suspension system of the low bed trailer contributes to its load-carrying capacity. Air suspension, mechanical suspension, or hydraulic suspension systems provide stability and support to handle heavy loads.

4. Trailer Design and Construction: The design and construction of the low bed trailer impact its overall strength and load-carrying capability. Factors such as the type of materials used, reinforced frames, and additional support structures influence the trailer's load capacity.

5. Legal and Regulatory Requirements: Load capacity is also influenced by the legal and regulatory requirements of the region where the low bed trailer operates. Different countries and jurisdictions have specific weight limits and regulations for transporting heavy loads on public roads.

Lowbed Trailer are usually used to transport a variety of machinery and equipment, heavy equipment, highway construction equipment, large tank body, power station equipment, and various excavators, and are used to transport heavy vehicles (such as tractors, coaches, Subway truck head, etc.), rail vehicles, mining machinery, forestry machinery, construction machinery (such as excavators, bulldozers, loaders, pavers, cranes, etc.) and other heavy-duty cargo.

The lower the platform height of the heavy load trailers, the better the stability and safety. Our low loader has a large carrying capacity when transporting extra high and medium cargo. TITAN semi low bed trailer height from ground is usually 1300mm. If you have special needs, we can also customize it for you.

There are many structures and styles of low deck trailer, 4 axle lowbed for sale in zimbabwe, 3 axle low bed trailer. Below we introduce the two most common styles.

1. The first structure of the low load trailer

Low flatbed trailer usually use a high-low frame, that is, the front section of the frame is a gooseneck (the traction pin at the front section of the gooseneck is connected to the traction saddle on the tractor, and the back end of the gooseneck is connected to the low bed semi trailer frame). The middle part is the cargo platform (lowest part of the frame).

This structure can transport a variety of heavy equipment, can also transport other general cargo, can also transport 40-foot containers, 20-foot containers. The export volume of machine carriers of this structural style to Africa is the largest.

4 axle lowbed, 4 axle low loader

2. The second structure of low flatbed trailer

Another structure commonly used in low loader for sale: a concave beam frame. The front section of the frame is gooseneck (the traction pin at the front section of the gooseneck is connected to the traction saddle on the tractor, and the back end of the gooseneck is connected to the heavy duty equipment trailer frame), the middle section is the cargo platform (the lowest part of the frame), and the rear end is Wheel frame (including wheels).

The low bed truck can also carry a wide range of goods, 4 axle low loader is suitable for the transportation of various steels such as a variety of mechanical equipment, large objects, highway construction equipment, power station equipment and machinery.

1. Working platform of low loader

The drop deck semi trailer main cargo platform is low, which ensures the stability of transportation and is suitable for carrying various types of engineering machinery, large equipment and steel.

Heavy semi low loader trailer Frame; Lightweight low loader Frame

Different frame styles determine its carrying capacity.

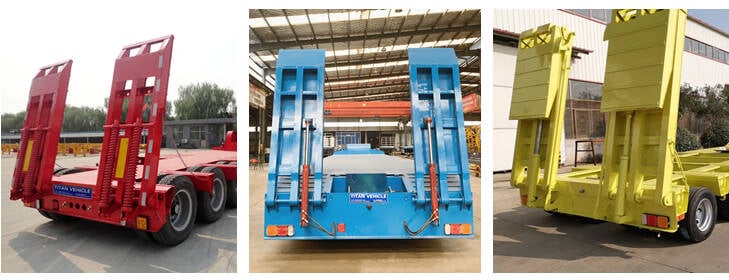

2. Low flat bed ramp

There are three styles of low loader trailer ramps, the most common is spring ladders. There are also ordinary hydraulic ramps and folding hydraulic ladders.

lowbed trailer manual, hydraulic and folding hydraulic ramps of low bed vehicle

3. Lowbed trailer suspension

There are three styles of step deck trailer and 3 axle low bed trailer suspension. The most common are leaf spring suspension, airbag suspension, and axis suspension.

The load capacity of the low bed semi trailer truck is mainly achieved by the frame, that is, the most important factor affecting the lowbed trailer load capacity is the frame. The stronger the 200 ton trailer of the frame, the better the carrying capacity.

200 ton trailer of tires has different models and designs, so tires also have a great impact on the load. The number and type of 2 axle low bed trailer axles, the thickness of the suspension, the thickness of the leaf spring, etc. also have a certain effect on the load.

There are many tonnages of low bed semi trailer we can provide, such as 2 axle low bed trailer, 15 tons low bed truck price, 30 tons low bed truck price, 40 tons low bed truck price, 60 tons low bed vehicle, 80 tons low bed vehicle, 100 tons low bed trailer truck, 120 tons low bed trailer truck, 150 tons low bed trailer truck, 200 tons low bed trailer, 200 ton trailer price. We can provide customized services according to the actual situation of transportation.

Many customers choose conventional models under 100t lowbed for sale in nigeria.

New Low Bed semi Trailer for sale

New Low Bed semi Trailer for sale

When loading mechanical equipment on a low deck trailer and 2 axle low bed tailer, it is usually loaded from the rear of the heavy load trailers, that is, by moving the mechanical equipment from the rear wheel frame or removing the wheels, and then fixing the mechanical equipment to the low bed loader.

What is the difference between detachable low bed and semi low bed trailer?

The major difference in low bed trailer price is that the gooseneck can be removed. When using a low bed trailer price, the heavy cargo is loaded from the rear part. However, the cargo is loaded from the front part when using a rgn lowboy trailer.

What is the height of the bearing surface of hydraulic low bed trailer manufacturers?

The most common hydraulic low bed trailer manufacturers height is 125cm. The low plate height purchased by African customers is 90cm, 100cm, 125cm, 130cm, and the minimum height can be 65cm.

In order to prevent the low bed lorry paint from being corroded by seawater, we spray a layer of wax on the surface of the low bed lorry before shipping and then cover it with a waterproof rain cloth.

low bed lorry, 150 ton trailer for sale

There are two types of lowbed trailer for sale ramps, namely, a mechanical ramp and a hydraulic ramp.

Mechanical ramp: A manual mechanism or a spring is used to lift the ramp to the right height. Lowbed trailer for sale mechanical ramp is cheap and easy to maintain.

Hydraulic ramp: With this type of ramp, low loader for sale in kenya of hydraulic cylinder is used instead of a spring to lift the ramp. 3 Axle low bed trailer hydraulic ramp is efficient and easy to use. You can move heavy cargo fast with a hydraulic ramp. However, the ramp is more expensive than a mechanical ramp.

Loading test of low bed lorry. All heavy haul trailer is tested for carrying capacity after production is finished.

Below is a test video of the TITAN 3 line 6 axle lowbed semi trailer.

low bed loader Test

Today, the classification of semi lowbed trailer occurs according to several parameters. The main criteria that influence the choice of a particular model or the order of a semi lowbed trailer are:

load capacity, platform height, dimensions, type of loading or type of entry on the trawl, design features, number of axles.

Already directly under your order, our technical man will offer you a semi lowbed trailer with characteristics and dimensions corresponding to the type and tonnage of the transported cargo, the loading option and the route of transportation of oversized cargo.

What are the standard dimensions, load capacity and dimensions of the semi lowbed trailer

Lowbed trailer dimensions are the most important criterion for choosing a platform for transporting oversized and heavy cargo. If you decide to buy a low loader trawl, then you should consider purchasing a more versatile platform that will allow you to perform a significantly wide range of tasks for transporting large sizes.

The size of the lowbed trailer for sale is one of the factors that determines the carrying capacity of this vehicle.

The carrying capacity, the height of the loading platform, the width and length of the lowbed trailer for sale are selected individually based on the size and weight of the oversized cargo, as well as on the characteristics of the route along which the cargo will move.

| Number of Axles | L*W*H(mm) | Loading Capacity(T) |

| 2 Axle | 12600x2500x2500 | 30-50T |

| 3 Axle | 14500x2500x2500 | 50T |

| 158000*3000*2500 | 60T | |

| 158000*3000*2500 | 80T | |

| 4 Axle | 165000*3000*2500 | 100T |

| 17000*3000*2500 | 120T | |

| 3 Line 6 Axle | 17200*3000*2500 | 120T |

| 17200*3000*2500 | 150T |

Welcome to leave your inquiry!

We will meet the acme of perfection to serve and provide more details, price, catalog, drawing, videos for you!