Low bed truck is a heavy-duty vehicle that is to transport heavy, wide, and tall cargo. Low bed trucks are used in different industries: heavy vehicles, rail vehicles, mining machinery, forestry machinery, construction, agricultural, etc, We can customize the low bed truck for you according to your needs.

Low bed trucks also can transport all categories of heavy loads. such as finished products from these industries are packed in containers and stacked on lowboys for transportation. The transporters can move stacks of heavy containers without toppling over. So, we also usually choose low bed semi trailers to transport heavy goods.

Low Bed Trucks Trailer for Sale in Nigeria Lagos

Low Bed Trucks Trailer for Sale in Nigeria Lagos

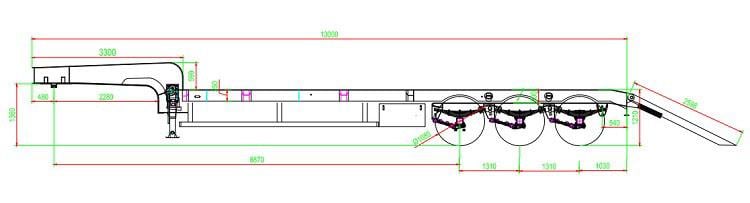

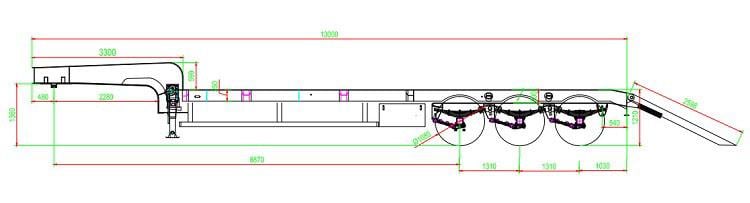

Low bed Truck dimension:

Model: TITAN 3 Axle Low Bed Truck

Dimension:13000mm * 3000mm *3400mm

Main beam: height: 500-550mm

Loading capacity:60 ton

Axles:3 axles

Suspension:spring suspension, air suspension

Tire:12 units

King pin:90#

Landing gear:JOST

Electrical system:24V, LED lights

Different types of Low bed Truck Trailer

Common Low bed Truck

The common low bed truck has a flat plate type, the cargo plate is a flatbed. There is a ramp at the end of the low bed truck trailer. The low bed truck is used to transport normal heavy cargo. It cannot transport cargo with a high height as other low bed trailers. This type of trailer has a higher working platform than other low bed trailers because of the flat plate type. The position of the working platform explains its limitations in transporting cargo with a high height.

One of the benefits of using the ordinary low bed truck is that it is cost-effective. The low bed truck is cheaper than other heavy-duty trailers. Another advantage is that the cargo platform is longer. The second half of the ordinary low bed trailers can be used as a cargo platform.

RGN trailer(removable gooseneck trailer)

Also known as a gooseneck lowboy trailer. The trailer frame has a stepped shape, and the plane of the cargo platform is behind the gooseneck, so that the main plane of the cargo platform is lowered, which is convenient for loading and unloading and transportation of goods. Our split gooseneck semi-trailer has a detachable gooseneck design on the front, which avoids overturning the body when transporting heavy equipment and ensures the safety of the vehicle and the driver.

Concave beam type low bed trailer

The low bed cargo platform is concave and has the lowest load-bearing plane. It is generally suitable for transporting large or ultra-high equipment.

The main advantage of a low bed truck is high stability. The staircase structure lowers the height of the cargo center, which increases stability during transportation. Low bed trailer is commonly used to move heavy equipment and cargo with a high height. It is best suited in countries that have strict height restrictions.

Advantage of Low bed Truck:

TITAN Low loader Trailer main beam adopts Q460C High Strength Steel Material

- Q460C steel has high yield strength, more durable and stronger than ordinary steel, and its loading capacity is 5 times more than the low loader which is built by Q345 steel. - Each ton of Q460C high strength steel costs double the price of ordinary Q345 steel material, ensuring that our TITAN low bed truck will have a long service life and avoiding unnecessary maintenance costs.

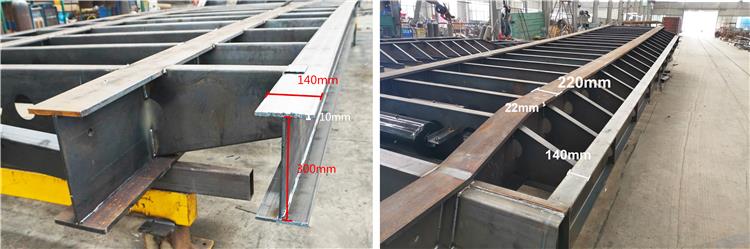

1. Main beam

500mm thickened Main Beam (Q460C high strenght steel)

TITAN low bed truck adopts 500mm main beam, effectively increase 10% loading capacity than the normal excavator trailer which uses 450mm main beam, and ensure the main beam resistance to twisting forces, shock and bump, meet load requirements on bad road, even no road.

300mm width Main Beam

TITAN low bed truck trailer adopts 300mm width main beam, increase 20% loading capacity than the normal low loader trailer which uses 140mm width main beam, ensure driving smoothly.

2. Side beam

300mm Height Side Beam

The side beam of TITAN low bed truck trailer adopts 300mm "I beam" design, and its loading capacity is 2 times more than the normal heavy haul trailer which uses 250mm side beam.

10mm thickness Side Beam

TITAN low bed truck is produced by 10mm thickness side beam, its loading capacity is much higher than the normal low loader trailer which uses 4.5mm thickness

3. Strong ramp

The loading ramps are made of T700 high strength steel, with high loading capacity, will not happen to the deformation when carry heavy equipment.

Components of the low bed truck trailer:

Suspension system: transfer load and absorb vibration.

Axle and hub system: A single, two and three axle assemblies of the same structure are installed under the suspension system.

Landing gear lifting system: In order to make the low bed truck price reliably parked after being separated from the truck, the front end of the frame is provided with two linkage or single action landing gear. It consists of a screw drive mechanism, a bevel gear drive mechanism, a two-speed reduction gearbox, a transmission rod, an operating handle, and so on.

When the handle is pushed in, the rotation can be raised and lowered at high speed, and when the handle is pulled out, the rotation can be raised and lowered at low speed. When the outriggers touch the ground, they can only be raised and lowered in low gear.

Traction pin: There is a traction pin connection plate connected to the tractor saddle at the lower part of the front end of the frame. The traction pin is mainly used to transmit the traction of the tractor and the braking force during braking.

Details of Low bed Truck Trailer for Sale in Nigeria Lagos

Semi trailer braking system: It is composed of the trachea connector, inflation pipe, operating channel, gas reservoir, brake air chamber, relay valve, ABS valve, ABS sensor and wheel brake of the tractor.

The inflatable tube is connected to the tractor’s gas tank through a quick pipe joint; it is connected to the tractor’s brake valve through a quick joint. When the low bed truck trailer brakes, each brake air chamber functions simultaneously.

Semi trailer airway: Three major parts: emergency relay valve, ABS valve, brake air chamber, most of the faults come from these three pieces.

Semi trailer circuit: The low bed truck trailer transmits the light signal of the main vehicle to the trailer by connecting the spiral cable plug of the truck to the circuit socket at the front of the trailer. Thus, the vehicle equip with an international general electrical system that matches the truck. The electrical system generally consists of seven core sockets, multi core cables, junction boxes, waterproof connectors, and various types of lamps and other components.

What are the factors that affect the stability of low bed truck?

The stability of the transport vehicle includes the stability of the strapping method and the stability of the low bed truck trailer operation.

1. The bundling stability is divided into bundling forward sliding stability, forward rolling stability, side sliding stability and rollover stability;

2. The running stability is divided into the horizontal stability of the trailer, the longitudinal stability of the trailer, the stability of the collapse of the low bed truck and the resulting local axle load increase, and the stability problems caused by the failure of some branches or components of the hydraulic system.

A large inertial force is formed during emergency braking of a low bed truck trailer train, which may cause the cargo to slide forward along the plane of the car body and the cargo to tip forward; when the low bed truck body is tilted laterally, the cargo may slide sideways or Pour sideways. Therefore, when the quality and outer dimensions of the cargo carried by the car train are very large, the design of the strapping scheme is generally required in advance to ensure the reliability of the strapping between the cargo and the low bed truck body. The higher the tipping resistance and the side slip resistance of the trailer, the better the stability, and the driving safety and other performance of the trailer are also improved. Therefore, in order to ensure the safety and reliability of the transportation process, it is necessary to consider the stability of the strapping method.

The running stability of the trailer is divided into lateral stability and longitudinal stability. The internal factors that affect its stability are mainly the width of the trailer, the height of the center of gravity of the cargo and the weight of the cargo. Under high wind conditions, the windward area of the cargo also affects its stability. The external factors that affect stability are mainly the cross slope, longitudinal slope and lateral strong wind of the road. Therefore, it is necessary to comprehensively consider various factors and determine under what extreme conditions the low bed truck trailer group will have horizontal or vertical stability.

Low Bed Trucks Trailer for Sale in Nigeria Lagos

Low Bed Trucks Trailer for Sale in Nigeria Lagos